| Размер | 1/2" | 3/4" | 1" | 1-1/4" | 1-1/2" | 2" | 2-1/2" | 3" | 4" |

|---|---|---|---|---|---|---|---|---|---|

| L | 110 | 110 | 130 | 130 | 150 | 160 | 170 | 180 | 200 |

| l1 | 40 | 45 | 50 | 55 | 60 | 65 | 75 | 85 | 100 |

| l | 9 | 10 | 11 | 13 | 15 | 17 | 19,5 | 22 | 25 |

| Цена 304 | 90 | 143 | 204 | 219 | 367 | 357 | 765 | 826 | ДОГ |

| Цена 316 | ДОГ | 551 | 255 | 255 | ДОГ | 561 | ДОГ | ДОГ | ДОГ |

Материал изделия - нержавеющая сталь

AISI 304 (08Х18Н10), AISI 316 (03Х17Н12М2)

Стандарт - DIN 2999

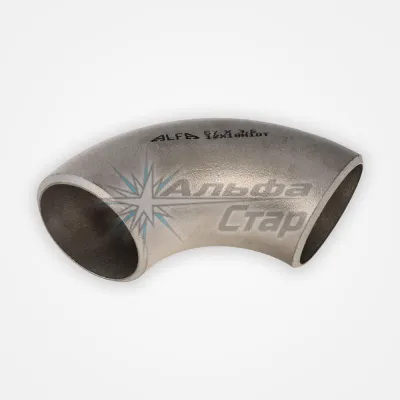

Сгон резьбовой нержавеющий

Сгон - фитинг для резьбового соединения в трубопроводах. Представляет собой полый цилиндр с резьбой на обоих концах. Длины резьбовых участков неодинаковы: с одной стороны - 5 – 6 витков, с другой - 20 – 30 витков. Сгон предназначен:

- для соединения смежных участков трубопровода, ни один из которых нельзя проворачивать;

- для подключения сантехнических, отопительных, газовых устройств;

- для создания дополнительных ответвлений трубопровода.

Соединение с использованием сгона выполняется следующим образом. Конец его с короткой резьбой завинчивается в резьбовую арматуру (муфта, тройник, отвод, кран, вентиль) на конце соединяемого участка с применением уплотняющих материалов (сантехнический лен, уплотняющая паста). На конец сгона с длинной резьбой навинчиваются контргайка и муфта, свободное пространство обматывается льном и обмазывается уплотнительной пастой. Этот конец стыкуется с соединяемой трубой, муфта на сгоне навинчивается до тех пор, пока не будет захватывать трубу. К муфте подвинчивается контргайка, оставив расстояние 2 – 3 см. Этот промежуток обматывается льном, контргайку поджимают к муфте, создавая прочное соединение. Оно обеспечивает простоту и экономичность ремонта и замены элементов трубопровода по сравнению с вырезанием участка трубы с последующей сваркой. Для трубопровода, работающего в коррозийных средах, например, проложенных в земле, или требующего соблюдения жестких санитарных норм (бытовой водопровод), необходимо применять сгон резьбовой из нержавеющей стали. Его антикоррозионные свойства и прочностные характеристики обеспечивают высокую надежность и долговечность трубопровода. Сгон из нержавейки прослужит в несколько раз дольше, чем обычный стальной или оцинкованный.

Компания АЛЬФА-СТАР предлагает этот распространенный вид фитингов в диапазоне типоразмеров ½" - 4” и длиной от 110 до 200 мм по стандарту DIN 2999. Материал изготовления - сталь AISI 304 (аналог 08Х18Н10) и AISI 316 (03Х17Н12М2). Сгон нержавеющий AISI 316 обладает повышенными антикоррозийными и прочностными характеристиками и может работать в кислотных и щелочных средах, включая морскую воду.