Stainless steel welding electrodes

Electrodes are consumables used in welding. They are divided into melting, which participate in the formation of the weld together with the molten metal, and non-melting. When welding with a non-melting electrode, the seam is formed due to additives contained in the electrode material.

Different types of electrodes are used for welding substances with different characteristics. Incorrect choice of consumables can lead to corrosion of the weld and its destruction. Since stainless steel is one of the most common materials used in industry, construction, design and in everyday life, stainless steel electrodes are especially in demand.

Our company offers two types of consumable welding material:

- electrodes for welding black and stainless steel Cromarod 316L manufactured by Elga (Sweden) with rutile coating. They have a reduced carbon content in their composition, which makes them suitable for welding acid-resistant AISI 316 steel. They can be used for welding thin-walled products. The formed seam is highly resistant to corrosion;

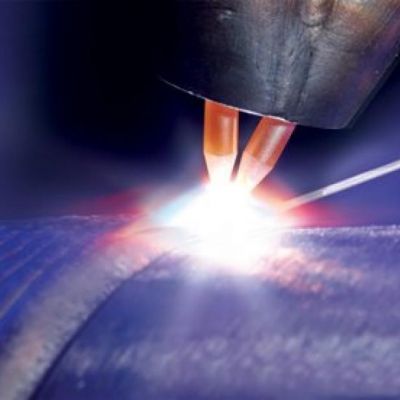

- tungsten electrodes. They can be used for welding various materials, including for joining black and stainless steel. They are used in argon-arc welding. We supply welding electrodes with additives of lanthanum oxide (type WL) and thorium dioxide (type WT). The lanthanum additive ensures high quality of the seam, practically free from tungsten impurities, low electrode wear and extended service life. WT electrodes are used for direct current welding of stainless and carbon steel, as well as titanium, copper and other metals.

The high quality of the offered welding materials guarantees the strength and durability of the joint. To buy the electrodes you need, contact our company by phone +7 (812) 457-05-59, +7 (812) 244-21-41, +7 (812) 244-21-42 or fill out an application on the website.