Tungsten electrodes

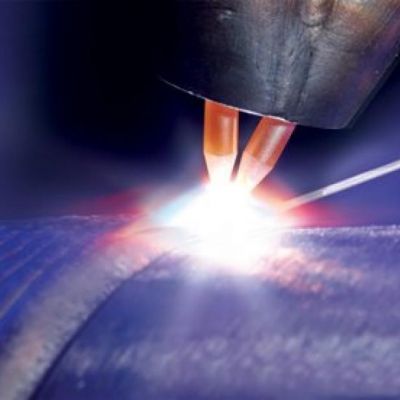

Tungsten electrodes are non-melting. Tungsten with a melting point of over 3000 °C, which is in their composition, practically does not participate in the formation of the welding seam. In addition to tungsten, the electrodes may contain additives that ensure high seam quality and long service life. Tungsten electrodes are used in argon-arc welding. This method is characterized by minimal impact on the metal surface. This reduces the likelihood of joint defects and has a positive effect on its strength and durability.

Tungsten electrodes are used for welding various metals and alloys: carbon and alloy steels, special alloys, copper, titanium, etc.

Our company supplies tungsten electrodes of the WL, WT and WY brands. They contain additives made of metal oxides: lanthanum (WL), thorium (WT) and yttrium (WY).

Lanthanated tungsten electrodes are among the most common. Their advantages:

- long service life;

- easy start of the welding arc;

- no metal burning;

- security;

- the ability to work on alternating and direct current.

Scope of application welding of high-alloy steels, copper, bronze, aluminum.

Thoriated electrodes were the first in time of occurrence. Durable, resistant to voltage fluctuations, easy to ignite. They are used for welding stainless and high-alloy steels, titanium and other refractory metals.

Yttriated tungsten electrodes have the highest resistance of all currently used. They are characterized by increased stability of the welding arc, which ensures high quality of the seam. They are used for welding all types of steel, as well as copper, titanium, cast iron, bronze, aluminum and rare metals. They work on direct and alternating current.