- Material: AISI304

- WEIGHT: 0.3

- DN: 65/32

- Ønar: 76,1/42,4/2

- PN:

- Material: AISI304

- WEIGHT: 0.26

- DN: 65/40

- Ønar: 76,1/48,3/2

- PN:

- Material: AISI304

- WEIGHT:

- DN:

- Ønar: 76,1/48,3/3

- PN:

- Material: AISI304

- WEIGHT:

- DN:

- Ønar: 76,1/57/3,0

- PN:

- Material: AISI304

- WEIGHT: 0.16

- DN: 65/50

- Ønar: 76,1/60,3/2

- PN:

- Material: AISI304

- WEIGHT:

- DN:

- Ønar: 76,1/63,5/1,5

- PN:

- Material: AISI304

- WEIGHT:

- DN:

- Ønar: 85/40/2

- PN:

- Material: AISI304

- WEIGHT:

- DN:

- Ønar: 85/52/2

- PN:

- Material: AISI304

- WEIGHT:

- DN:

- Ønar: 85/70/2

- PN:

- Material: AISI304

- WEIGHT: 0.43

- DN: 80/40

- Ønar: 88,9/48,3/2

- PN:

- Material: AISI304

- WEIGHT: 0.32

- DN: 80/50

- Ønar: 88,9/60,3/2

- PN:

- Material: AISI304

- WEIGHT: 0.16

- DN: 80/65

- Ønar: 88,9/76,1/2

- PN:

- Material: AISI304

- WEIGHT:

- DN:

- Ønar: 101,6/76,1/1,6

- PN:

- Material: AISI304

- WEIGHT:

- DN:

- Ønar: 101,6/88,9/3

- PN:

- Material: AISI304

- WEIGHT:

- DN:

- Ønar: 104/50,8/2

- PN:

- Material: AISI304

- WEIGHT:

- DN:

- Ønar: 104/52/2

- PN:

- Material: AISI304

- WEIGHT:

- DN:

- Ønar: 104/63,5/2

- PN:

- Material: AISI304

- WEIGHT:

- DN:

- Ønar: 104/70/2

- PN:

- Material: AISI304

- WEIGHT:

- DN:

- Ønar: 104/76,1/2

- PN:

- Material: AISI304

- WEIGHT:

- DN:

- Ønar: 104/85/2

- PN:

- Material: AISI304

- WEIGHT:

- DN:

- Ønar: 108/88,9/3

- PN:

- Material: AISI304

- WEIGHT: 0.71

- DN: 100/50

- Ønar: 114,3/60,3/2

- PN:

| DN | Ønar, mm | L, mm | e, mm | Weight (kg) | Price 304 | Price 316 |

|---|---|---|---|---|---|---|

| 8 | 13,5 | 20 | 1,6 | 0,025 | DOG | DOG |

| 8 | 13,5 | 20 | 2,3 | 0,035 | DOG | DOG |

| 10 | 17,2 | 25 | 1,6 | 0,03 | DOG | DOG |

| 10 | 17,2 | 25 | 2,3 | 0,045 | DOG | DOG |

| 15 | 21,3 | 27 | 1,6 | 0,04 | DOG | DOG |

| 15 | 21,3 | 27 | 2 | 0,05 | 135 | 142 |

| 15 | 21,3 | 27 | 2,6 | 0,065 | DOG | DOG |

| 15 | 21,3 | 38 | 1,6 | 0,04 | DOG | DOG |

| 15 | 21,3 | 38 | 2 | 0,05 | 135 | 142 |

| 15 | 21,3 | 38 | 2,6 | 0,065 | DOG | DOG |

| 20 | 26,9 | 28 | 1,6 | 0,048 | DOG | DOG |

| 20 | 26,9 | 28 | 2 | 0,06 | 161 | 160 |

| 20 | 26,9 | 28 | 2,6 | 0,08 | DOG | DOG |

| 25 | 33,7 | 38 | 1,6 | 0,08 | DOG | DOG |

| 25 | 33,7 | 38 | 2 | 0,1 | 204 | 250 |

| 25 | 33,7 | 38 | 3,2 | 0,22 | DOG | DOG |

| 32 | 42,4 | 47 | 1,6 | 0,12 | DOG | DOG |

| 32 | 42,4 | 47 | 2 | 0,15 | 237 | 290 |

| 32 | 42,4 | 47 | 3,2 | 0,25 | DOG | DOG |

| 40 | 48,3 | 57 | 1,6 | 0,17 | DOG | DOG |

| 40 | 48,3 | 57 | 2 | 0,21 | 375 | DOG |

| 40 | 48,3 | 57 | 3,2 | 0,36 | DOG | DOG |

| 50 | 60,3 | 76 | 1,6 | 0,28 | DOG | DOG |

| 50 | 60,3 | 76 | 2 | 0,35 | 410 | DOG |

| 50 | 60,3 | 76 | 3 | 0,52 | 580 | 800 |

| 50 | 60,3 | 76 | 3,6 | 0,56 | DOG | DOG |

| 65 | 76,1 | 95 | 2 | 0,56 | 644 | 816 |

| 65 | 76,1 | 95 | 3 | 0,84 | 800 | DOG |

| 65 | 76,1 | 95 | 3,6 | 1,2 | DOG | DOG |

| 80 | 88,9 | 114 | 2 | 0,78 | 923 | 1090 |

| 80 | 88,9 | 114 | 3 | 1,17 | DOG | DOG |

| 80 | 88,9 | 114 | 4 | 1,8 | 1400 | DOG |

| 100 | 114,3 | 152 | 2 | 1,35 | 1450 | 1600 |

| 100 | 114,3 | 152 | 3 | 2,02 | 1800 | DOG |

| 125 | 139,7 | 190 | 2 | 1,56 | 2250 | 2754 |

| 125 | 139,7 | 190 | 3 | 2,34 | 2750 | DOG |

| 150 | 168,3 | 228 | 2 | 2,99 | 3150 | DOG |

| 150 | 168,3 | 228 | 3 | 4,48 | DOG | DOG |

| 200 | 219,1 | 305 | 2 | 5,5 | 4794 | 5865 |

| 200 | 219,1 | 305 | 3 | 7,78 | 5916 | 10277 |

| 250 | 273 | 381 | 2 | 8,5 | 10710 | 12900 |

| 250 | 273 | 381 | 3 | 12,14 | 13000 | 13700 |

| 300 | 323,9 | 457 | 2 | 11,7 | DOG | DOG |

| 300 | 323,9 | 457 | 3 | 17,3 | 20951 | 22800 |

| 350 | 355,6 | 533 | 3 | 22 | DOG | DOG |

| 400 | 406,4 | 610 | 3 | 29 | DOG | DOG |

| 450 | 457 | 686 | 3 | 36,75 | DOG | DOG |

| 500 | 508 | 762 | 3 | 45,39 | DOG | DOG |

| 600 | 609,6 | 914 | 3 | 64,9 | DOG | DOG |

Product material - stainless steel

AISI 304 (08X18H10), AISI 316 (03X17H14M2)

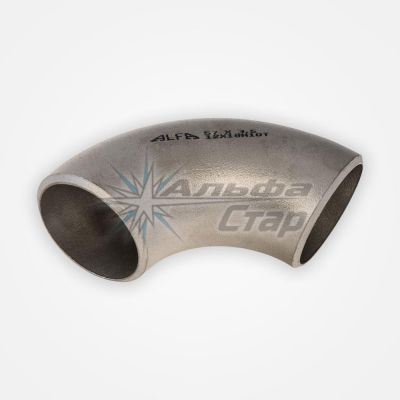

Stainless steel 90 0 welded electric welded DIN

Stainless steel tap is widely used in pipelines for various purposes, including in the food, chemical, pharmaceutical and oil and gas industries, in energy, housing and communal services and other industries. Our company offers stainless seamless and electro-welded bends. They are welded end-to-end to the pipes to be connected or to their walls in case of mismatch of diameters, forming a strong seam that ensures complete tightness of the connection. Electric welded tap, unlike seamless tap, is not used in high-pressure pipelines. But it is much cheaper and is a reasonable solution for pipeline sections that do not experience high loads. Electrowelded bends are made from fragments of an electrowelded pipe, which are subjected to bending on special equipment and surface finishing. The rotation angle can be 45º and 90º. The most common 90º bends connecting sections of the pipeline at right angles.

ALFA-STAR company offers this type of products manufactured according to the DIN standard (German abbreviation for the German Institute for Standardization). The material of manufacture is stainless steel AISI 304 (08X18H10), AISI 316 (03X17H14M2). AISI 304 steel belongs to the food grade. Taps in this design are characterized by high corrosion resistance, environmental friendliness and hygienic cleanliness and can be used in food, pharmaceutical and chemical industries with a working environment of low and medium aggressiveness, in conditions of high humidity. The AISI 316 version (acid-resistant heat-resistant steel) is intended for use in environments with higher aggressiveness, in seawater, salt and chlorine-containing solutions, at elevated temperatures. Stainless electric-welded bends work well for compression, are reliable and durable when operating conditions are met.

Stainless electro-welded din tap is offered in a wide range of sizes DN (nominal inner diameter), starting from a value of 8 mm to 600 mm. Each DN value corresponds to from 1 to 6 standard sizes of products differing in outer diameter, wall thickness, and working length. This allows you to choose the optimal size of the outlet for pipeline sections that are diverse in characteristics. We are direct suppliers of products, which favorably affects its price with high quality products.